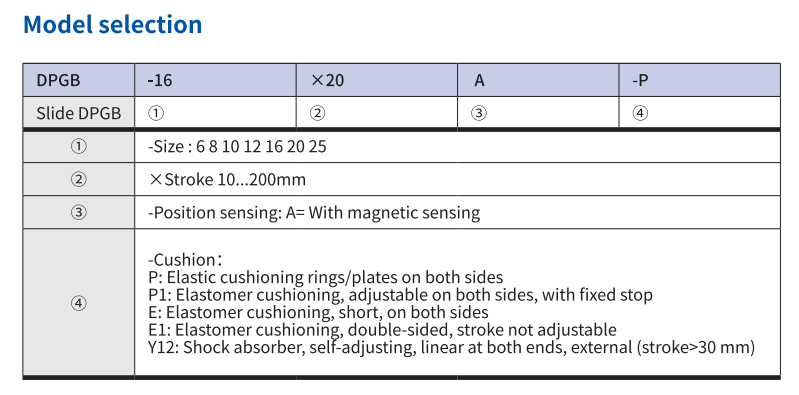

DPGB small slide cylinder

Cylinder diameter: 6,8,10, 12, 16, 20, 25

• Compact structure, large feed force

• Simple structure with symmetrical mounting interface

Installation and Use

1. When there are changes in load during work, cylinders with sufficient output force should be selected;

2. Under high temperature or corrosive conditions, corresponding high-temperature or corrosion-resistant cylinders should be selected;

3. In places with high humidity, high dust, or water droplets, oil dust, or welding slag, corresponding protective measures should be taken for the cylinder;

4. Before connecting the cylinder to the pipeline, the dirt inside the pipeline must be removed to prevent dust and other debris from entering the cylinder;

5. The medium used in the cylinder should be filtered with a filter element of over 40um before use;

6. Due to the short front cover and piston of the cylinder, the general stroke should not be too large;

7. In low temperature environments, anti freezing measures should be taken to prevent moisture freezing in the system;

8. During the working process, the cylinder should avoid being subjected to lateral loads as much as possible to maintain its normal operation and service life;

9. If the cylinder is removed and not used for a long time, attention should be paid to surface rust prevention, and dust blocking caps should be added to the intake and exhaust ports. Special attention should be paid: the front and rear covers cannot be disassembled by themselves;

10. Installation and disassembly of C-type buckle:

10.1. When assembling and disassembling, it is necessary to use suitable pliers (C-type buckle installation tool) to ensure safety and avoid damage to the human body or surrounding machines caused by the C-type buckle flying out;

10.2. Ensure that the C-type retaining ring is installed in the groove of the body retaining ring before ventilation.

安装与使用

1、 工作中负载有变化时,应选用输出力充裕的气缸;

2、 在高温或者腐蚀性条件下,应选用相应的耐高温或耐腐蚀性气缸;

3、 在湿度大,粉尘多,或者有水滴、油尘、焊渣的场合,气缸应采取相应的防护措施;

4、 气缸接入管道前,必须清除管道内脏物,防止粉尘等杂物进入气缸内;

5、 气缸使用介质应经过40um以上滤芯过濾后方可使用;

6、 因气缸前盖及活塞均较短,一般行程不可选择太大;

7、在低温环境下,应采取抗冻措施,防止系统中的水分冻结;

8、气缸在工作过程中应尽可能避免受侧向载荷,以维持气缸的正常工作和使用寿命;

9、气缸拆下长时间不使用,要注意表面防锈,进排气口应加防尘堵塞帽, 特别注意:前、后盖不可自行拆卸;

10、C型扣环的装拆:

10.1、装拆时一定要使用合适的手钳(C型扣环安装工具)进行,确保安全, 避免因C型扣环飞出,对人体或周边机器造成损害;

10.2、确保C型扣环装入本体扣环沟槽后,方可通气。

Add: No.12 HengliRoad Wujin District Changzhou

Tel: 0510-85590763/85591888 / Technology: 0510-85597409 / Fax: 051085599255

Postal Code: 213169

E-mail:sales@wxhengli.com

Monday to Friday 8:00~17:00

Hengli Pneumatic

Add wechat

View wap